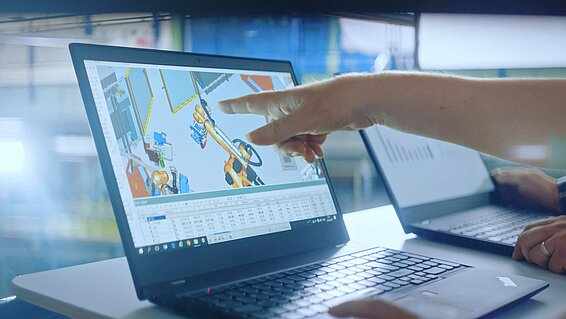

Intelligent production control makes all the difference and transforms contemporary production facilities into future-ready smart factories. Leadec also relies on in-house software solutions for this.

Production planning and optimization

Together with our customers, we go the entire way from process and area planning to the detailed planning of lines and plants and factory simulation to support with implementation. Whether greenfield or brownfield - we are at home in both worlds. The optimization of your processes with MTM, lean or CIP methods is just as much a part of our services as the corresponding logistics planning. Together we create the conditions for more productivity, process reliability and flexibility. Automobile manufacturers and their suppliers worldwide use our specific knowledge and many years of experience for large-scale production with a high number of variants and just-in-time or just-in-sequence requirements. Many medium-sized companies with very small production and batch sizes also benefit.